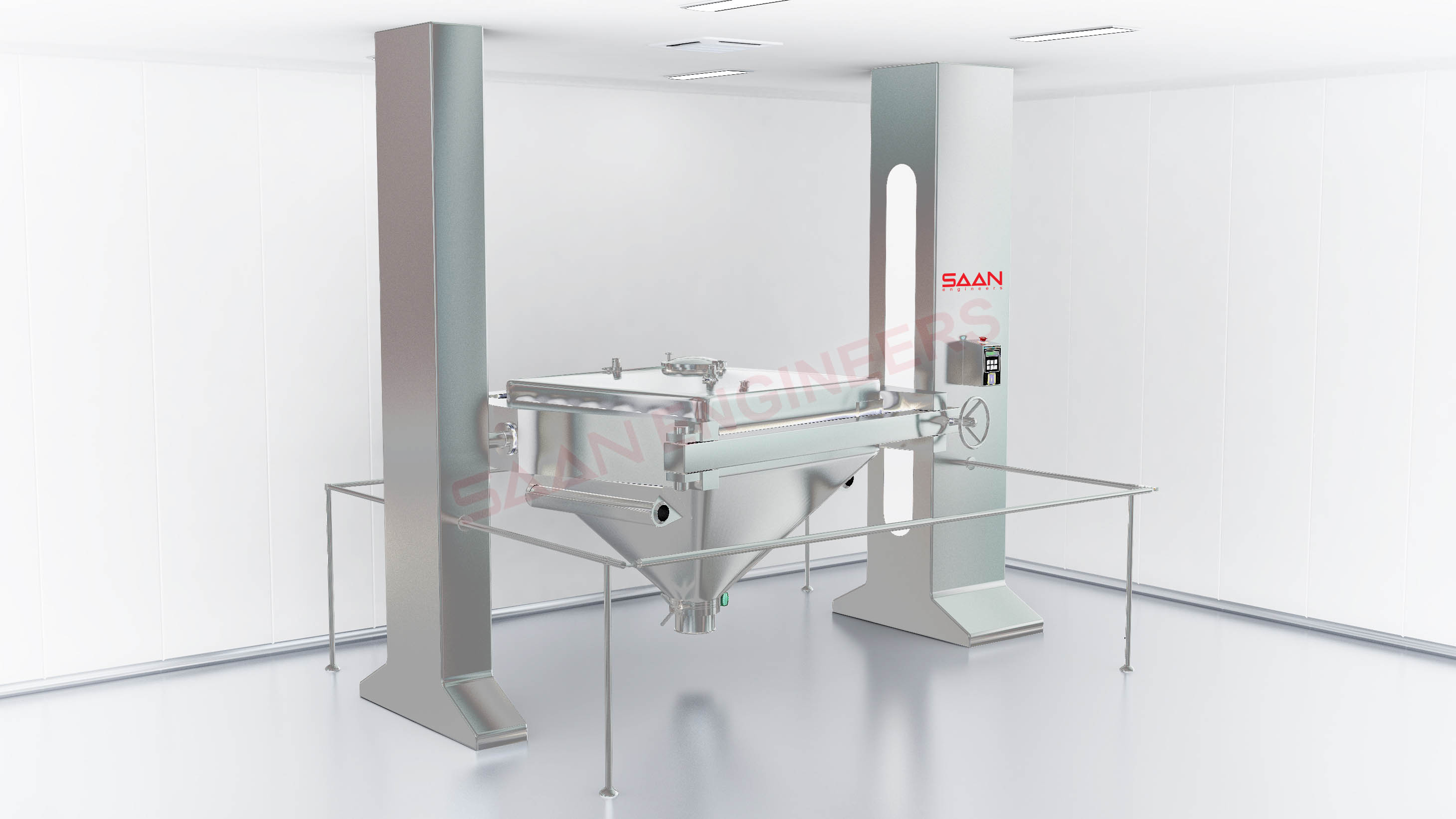

One of the perfect example of batch blending where sized granules collected in a container, docked to the blender arm, clamped, lifted from a single end and tumbled for the pre-validated time.

The low shear blending action prevents excessive fines or changes to particle shape or size. Fast loading, complete discharge, short cycle time, low powder requirement and minimum maintenance are some of the features.

Conta blending improves efficiency compared to conventional blenders because of mixing in the diagonal and eccentric planes.

Enormous flexibility – different capacity of bins (for e.g. 200 Ltrs., 400 Ltrs., 600 Ltrs.) can be docked in the single fork of the same conta blender. Also various shapes of bin can be accommodated. (For eg: You could dock an Octagonal / V Shaped Blender body in the same arm of the Conta bin)

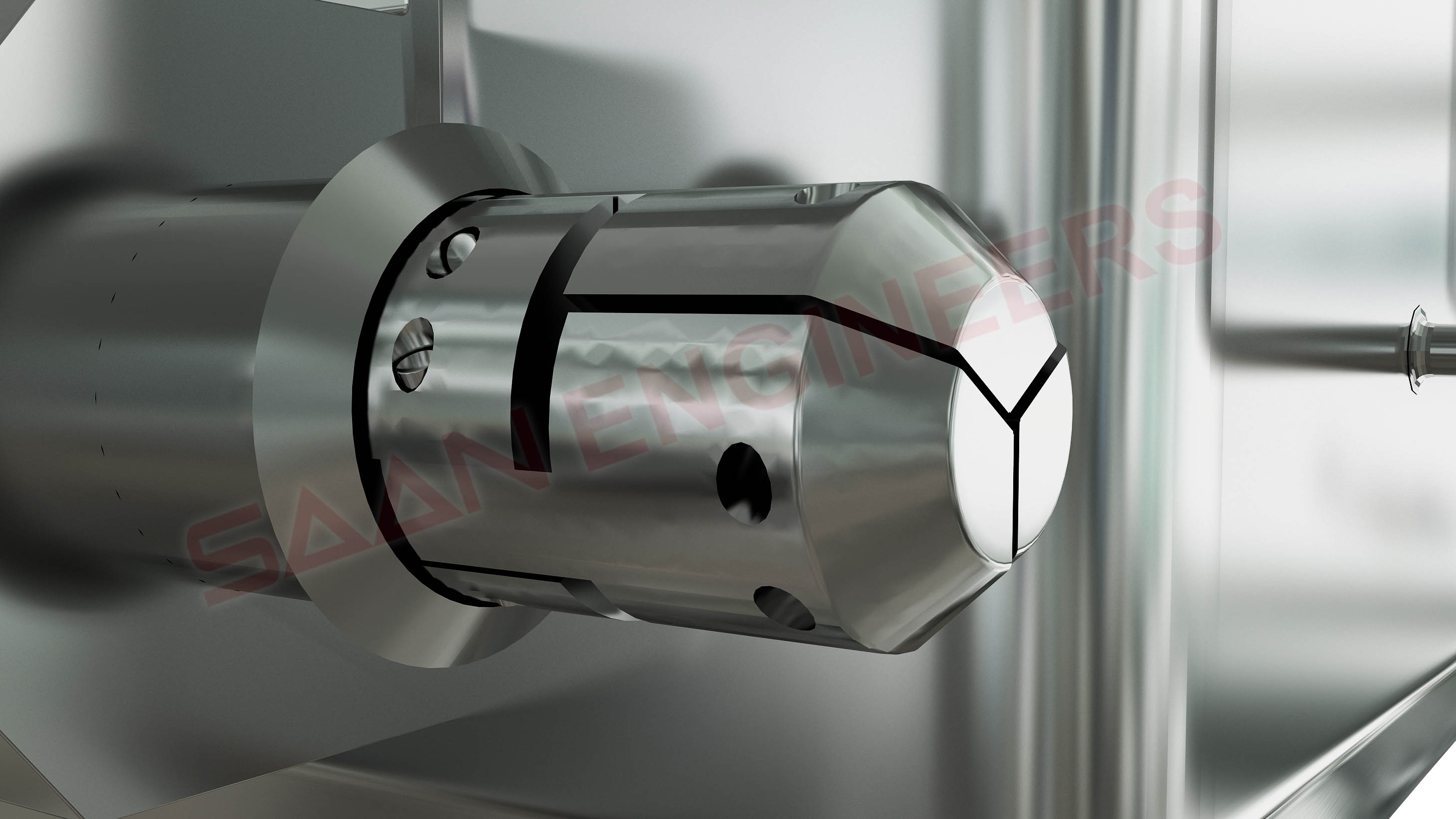

The arm of the bin blender does not have any nylon rollers or pins. It is a simple sliding system with a wedge arrangement for resting.